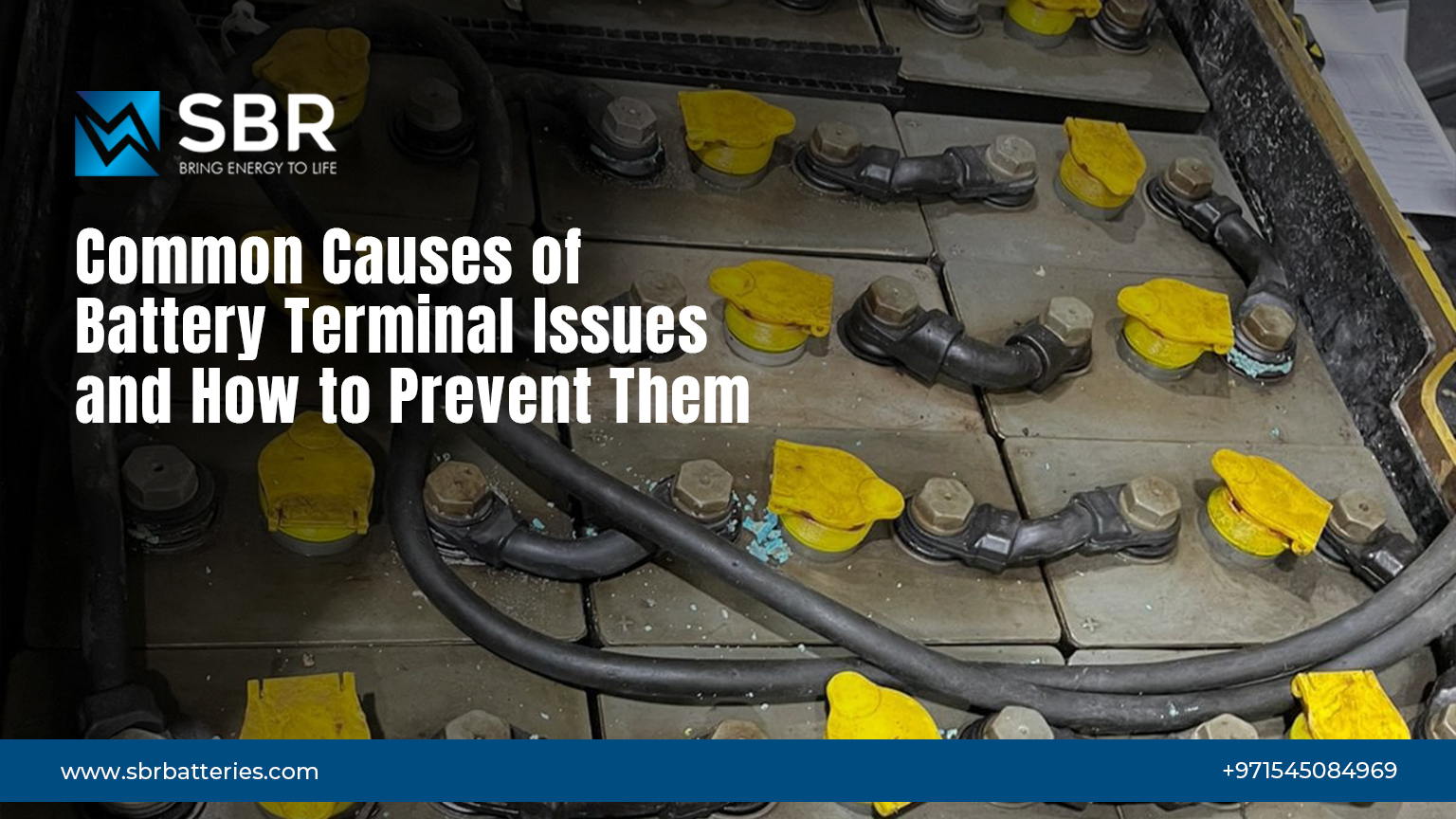

Common Causes of Battery Terminal Issues and How to Prevent Them

Battery terminal is an integral part of all electrical systems which connects critical parts of machines to various divisions, ensuring a smooth flow of electric current. Every electrical component is prone to wear and tear in the long run; therefore, batteries are no exception. An in-depth idea of what causes a bad battery and how to prevent it is key to maintaining a healthy machinery. In this blog, we will discuss various factors that lead to battery terminal issues and what to look for.

But First ; What is a Battery Terminal?

A battery terminal is a metallic connector located at the top side of a battery, which is a serving point that acts as the point of contact between the battery and the electrical system. Usually, there are two kinds, positive (+) and negative (-), and the metals used are lead, copper, or brass. Your battery won’t deliver significant power without a properly functional terminal.

What is the Key Cause for a Battery Terminal

Generally, there are various factors that can contribute to a bad battery terminal, mainly:-

- Unwarranted Corrosion

When the sulphuric acid in batteries gradually releases toxic gases it can easily undergo chemical reactions with the metal terminal which can form a slurry white / bluish contaminant.

- Usual Wear

The degradation of the terminal occurs overtime by the usual heat exposure,cold or moisture contents. This is a natural wear and tear which can only be postponed with excellent battery care.

- Lazy / Loose Connections

Suppose the battery terminals are not securely fastened to the battery posts. In that case, electrical arcing might occur, damaging both the battery terminal and the posts. Irregular power delivery is also one potential issue with loose connections.

- Low Grade Materials

Inferior materials always cause headaches, and you don’t want a fresh pair of such headaches, do you? So, low-grade terminals can corrode pretty easily. Therefore, always remember that a quality battery terminal has a prolonged life.

What are the Early Signs of a Bad battery

Usually if you are experiencing some kind of problem with your machinery equipment , then it might be the battery terminal. These are some common signs.

1.Difficulty in Starting up Machines

Faulty terminals are bound to hinder the power delivery of the battery to the starter motor, which causes slow cranking or a complete failure.

2.Frequent Charging Cycles

One of the key issues, a damaged battery can show would be frequent battery cycles, that us a decrease in the battery capacity. As a result, you might be required to charge batteries pretty often.

3.Physical Damage

Visible damages to the terminals – mainly cracks, bends or breaks can be an indicator of connection compromises, which is detrimental for your battery performance.

4.Corrosion Build up in the Terminal

The appearance of corrosion, which frequently manifests as a white, powdery material, is a certain sign of terminal problems. Additionally, it may show up as greenish or bluish deposits on the terminals.

Tips for Preventing a Bad battery terminal

Repair is never as effective as prevention. The following useful advice will help you keep your battery connections in top shape:

1. Consistent Inspections

To identify problems early, check your battery terminals for corrosion, damage, or loose connections at least once a month.

2. Maintain Clean Terminals

Using a solution of baking soda and water, clean the terminals on a regular basis to get rid of corrosion, dirt, and grime.

3. Make use of terminal protectors

To protect the terminals from moisture and corrosive gasses, use felt washers or terminal caps.

4. Do not overcharge

Acid leaks from overcharging your battery might hasten terminal deterioration. Maintain appropriate charging levels by using a smart charger.

Conclusion

Battery terminal is one of the key components of Industrial batteries, therefore should be maintained as such. If these tips are devices to prolong the life of the battery terminal, then it might last till 6 years. SBR Batteries offer comprehensive industrial battery solutions in UAE, which are critical to avoid battery corrosions and tears. The important takeaway is, always use quality components, be it battery or any other parts.

SBR for the last several years has been in partnership with industry experts and leaders to come up with the most comprehensive battery solutions.